|

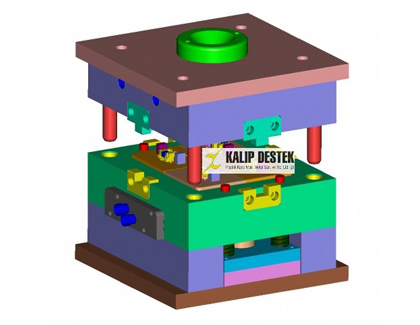

KALIP DESTEK Plastic and metal injection molds are designed and produced by care and quality which come from many years of experience by our experienced designers and mold makers.

Mold production stages:

After taking fore knowledge and technical data from our costumer for the design of the mold, the mold design is started. After the mold design is completed, the production stages are started. Part designs are sent to the CNC, EDM and conventional mold production. Simultaneously, order of mold setting, section and equipment is given. After these procedures, the montage and final controls of the molds are made and then despatched to injection department. The first samples of mold which are attached to the plastic injection machine that is suitable for tonnage are made and are measured to check the molds that have been made. The molds of accepted products are dispatched according to the costumer's demand or subcontracted to injection molding that are made in the plastic injection machines in our company.

|